10 Best 3D Printing Meme Ideas

As the year is still new, it's time to refresh some amazing 3D printing memes! The previous several years have certainly been an up-and-down journey, and that is something that we cannot dispute. At times, laughter is the only way to get through all of the crazy. There are always memes to keep you delighted, such as good morning memes, happy birthday memes, wholesome memes, cat memes, and puppy memes; however, this compilation is all about the best of the best in the 3D industry![br][br][br]

A meme is "a humorous or fascinating object (such as a captioned photo or video) or genre of things that gets distributed extensively online, particularly via social media." Memes are often composed of funny pictures and text and are frequently utilized as a form of social or political criticism. [br][br]A GIF, however, is not the same thing as a meme. A moving picture file known as a GIF is almost identical to a brief video clip taken from a movie. After then, the video is played in a never-ending loop. GIFs are distinct from memes in that they are animated, while memes are often still images.[br][br]Because there are so many humorous memes floating around the internet, you've probably given some consideration to trying your hand at making one of your own. You can create memes with the help of several different applications and tools, like Canva and Imgur, both of which have built-in meme generators and even Photoshop. [br][br]If you want some meme ideas for the 3D industry, we have you covered! Let's look at some of the most popular meme ideas!

Desperate times indeed call for desperate measures. Did you realize that a 3D printer may perform functions other than those of a traditional printer? This may be the most effective way to fry your dino nuggets! If you ever need an oven or stove, you may want to consider using your 3D printer as an alternative. We all have once been in such a situation more often than we like to admit. But this meme covers it all![br][br][br]

There always comes a moment in everyone's lives when they can't find the right resources for upgrading their skills. On the one hand, it can be used to make a meme, but on the other, we also offer you a solution to your troubles. [br][br]SelfCAD can help you prepare designs for 3D printing all in one program without having to switch to a different software. In addition to easy to use and powerful tools, SelfCAD also has a powerful [url=http://www.selfcad.com/slicer]Online Slicer[/url] that you can use to slice your designs without needing a separate software. This efficiency gives you even more reasons on just how self-sufficient the software is, and its ability to meet your 3D designing and printing needs. [br][br][br]

Finally, a way to trick the boss. Funny, isn't it? Can you see a 3D-printed version of yourself? Share with us the crazy ideas you would implement if you had a copy of yourself to play handle! With so many options up your sleeve, the first is to scare your friends with a twin they never knew existed![br][br][br]

Are you still living in the past, or are you all caught up with today's technology? With the speedy technological advances, 3D printing is gaining popularity with every passing day, so much so that people still using 2D are being seen as targets for a hilarious meme!

This meme is witty, yet it also offers us all something to think about. When one achieves success in a task that was earlier seen as very difficult or unattainable, one always experiences a sense of satisfaction. Who'd have even thought of a 3D printer before? But can you print a car in 3D? As long as one doesn't start running on the streets, it is the target for good humor in the 3D industry![br][br][br]

This meme definitely makes us think of a cool name for a 3D- printed oven. But if it were a game, what would you call a 3D-printed oven? As long as we get cooked meals out of it, we wouldn't mind calling it a hea-oven! But if this became possible, quite a lot of industries might come crashing down, and people might start printing all their stuff from scratch, maybe their own 3D printers too!

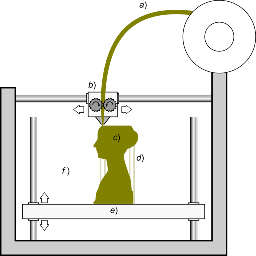

Knowing the printer specifications and requirements is a must for 3D printing. 3D printing isn't as easy as it seems. Without the right settings, the end product might not look as you had imagined! You might want to print one thing but come up with completely different end products. But by properly setting your 3D printer and designing your model appropriately in programs like SelfCAD, you can overcome most of your 3D printing troubles .

Has it ever happened to you before? You turn your back for a second, and everything goes completely crazy! If you came up with one such situation, we bet you are all prepared to start 3D printing because it is like boiling milk at the right temperature! You take your eyes off for one split second, and you won't know what hit you! Feel free to share with us some of your crazy 3D printing stories!

All jokes aside, what if we tell you there are actual figurines of the funniest and most popular memes available for purchase? Now, this is what we call "thinking outside the box." It is just amazing how memes can now be in 3D-printed versions. Gift these statuettes to your friends and be the best gift giver! You can check more such hilarious 3D figurines.[br][br][br]

Depressed? Sad? Find yourself someone who can cheer you up, like the dad who printed a wooden elephant for his child! Who thought 3D printing could be the best thing to relax your mood? But isn't that just the best way to make someone smile? Who is crying? You are. Someone, please give him the 3D-printed "World's Best Dad" mug.[br][br][br]

We hope these memes made you laugh and got your creative juices flowing for making more such hilarious content. What most people don't realize is that creating memes is an art. It's about hitting the right spot for the humor to be relatable. The creation and maintenance of a design system is a time-intensive process.[br][br]One can sense that memes are static, unique creations that, in most instances, do not need reusable components. However, this is not the case. Whether or not this perception is correct, it may signal that there is a lack of consistent strategy across projects and that an opportunity to enhance efficiency has been missed.[br][br][br]